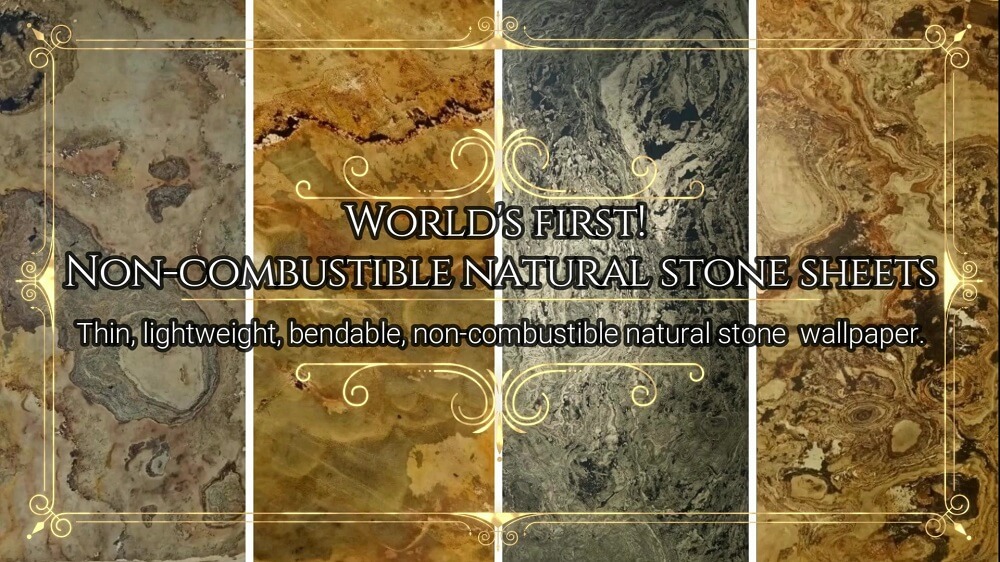

Natural stone sheet (Noncombustible Stone Veneer)

What is a natural stone sheet (Flexible Stone Veneer)?

Natural stone sheet (Flexible stone veneer) is an innovative finishing material made of thinly peeled sheets of natural rock. Although made of real natural stone, it is thin, lightweight, easy to cut with scissors, and bendable, making it possible to install even on curved surfaces such as cylindrical columns.

Using natural stone sheets as a finishing material, you can easily create a luxurious hotel-like space just by applying them. Because real natural stone is used, each sheet is a one-of-a-kind product, and the variety of natural stone designs created by nature over the years is soothing.

Natural stone sheets are a popular finishing material sold around the world, but their disadvantage is that they are backed with resin and fiberglass, which makes them flammable. For this reason, it is impossible to obtain certification as a noncombustible material.

However, at Each DreaM, we have succeeded in developing the world’s first natural stone sheet that does not burn. We are the only company in the world that offers completely non-combustible natural stone sheets, and in April 2023, we passed the Ministry of Land, Infrastructure, Transport and Tourism’s certification for noncombustibility.

History of Natural Stone Sheets (Flexible Stone Veneer)

It began when a German furniture designer accidentally discovered that when trying to remove natural stone tiles from a broken table top, the surface layer of the natural stone peeled off and remained attached to the resin, and after research and development, was granted a patent. Today, it is produced and sold worldwide.

Applications of natural stone sheets (DIY wall decoration, furniture remake, etc.)

Natural stone sheets can be used as a finishing material for walls, columns, ceilings, curved wall surfaces, furniture, lightweight signs, lighting, cabinets, doors, and many other areas. It is also suitable for DIY remodeling of stores and houses, and furniture remodeling.

Non-combustible natural stone sheet (Noncombustible Stone Veneer)

World’s first! Completely non-combustible natural stone sheets. [ Non-combustible wallpaper ]

Each DreaM has developed the world’s first incombustible natural stone sheet.

We are the only company in the world that has a natural stone sheet that does not burn.

This sheet is made of real natural stone that can be used as incombustible wallpaper.

In April 2023, the company passed the Minister of Land, Infrastructure, Transport and Tourism’s certification examination.

Natural stone sheets made by Each DreaM are backed by our special technology and our own fiber reinforced ceramic (FRC) and basalt fibers, and will not burn because all the constituent materials are made of incombustible materials.

Like natural stone sheets sold around the world, it is thin, lightweight, flexible, bendable, and can be easily cut with scissors. In addition to the features of conventional natural stone sheets, Each DreaM’s natural stone sheets have the added feature of being non-combustible.

Please check the video. You can see the thinness of about 1mm, flexibility, and non-inflammability.

The main characteristics of natural stone sheets (noncombustible wallpaper) made by Each DreaM

Passed the test approved by the Minister of Land, Infrastructure, Transport and Tourism (heat generation test / ISO-5660)

Natural stone sheet (Noncombustible material certification number: NM-5646)

Data from the Ministry of Land, Infrastructure, Transport and Tourism’s noncombustible material certification test for natural stone sheets.

This is a thin sheet of natural stone peeled off to a thickness of about 1 mm.

Test number: ⅢY-22-0131

Exothermicity Test

Test Date: April 6, 2023

Radiant intensity: 50 kW/m2

Test duration: 20 min

Result: Technically approved by the evaluation committee.

Evaluation No.: GBRC Construction Review-23-021A-008

Natural stone board (Noncombustible material certification number: NM-5645)

This is the data from the Ministry of Land, Infrastructure, Transport and Tourism’s noncombustible material certification test for natural stone board. Natural stone board is a natural stone sheet crimped to a calcium silicate board.

Test number: ⅢY-22-0130

Exothermicity Test

Test Date: April 6, 2023

Radiant intensity: 50 kW/m2

Test duration: 20 min

Result: Technically approved by the evaluation committee.

Evaluation No.: GBRC Construction Review-23-021A-007

Natural stone sheet (Product name: Beyond the Stone) type list

Natural stone sheet (noncombustible material certification number: NM-5646)

Natural stone board (noncombustible material certification number: NM-5645)

Size and Price

| Natural stone sheet type | Size | Price |

|---|---|---|

| Soft Type [Basalt cloth use] ※Ideal for curved locations |

| negotiable |

| Hard Type [Basalt mat used] ※Ideal for flat areas |

| Please contact us |

| Board Type [Compression bonded to calcium silicate plate] ※High fire resistance |

| Please contact us |

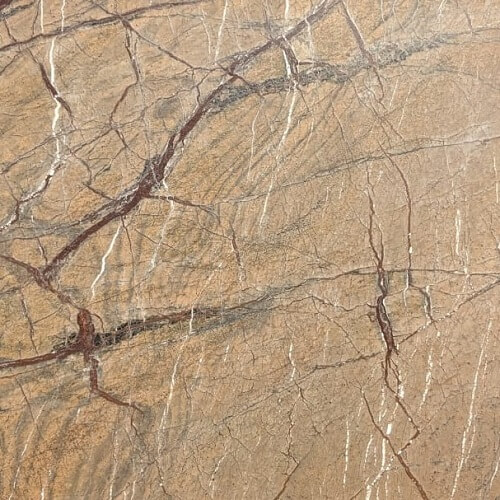

Even the exact same natural stone (e.g., Peacock) has such a wide range of color gradations.

Because we use natural stones, even the same stone can have a wide range of colors. During the manufacturing process of stone veneer, when the sheet is peeled off, layers of different colors may appear, and even if natural stones with the same name are imported, the colors may vary. For example, the stone veneer shown below is made from Indian slate peacock, and there is such a wide range of colors. When ordering natural stone, which is the material, we order it by the name of the stone, but it is very difficult to deliver manufactured stone veneer in the same color range because we cannot specify the color and it is delivered in such a color range. On the other hand, this range of colors is the appeal of natural stone, and I think that by pasting stone veneer of different colors in a well-balanced manner, you can create a space with an attractive design.

Color variation

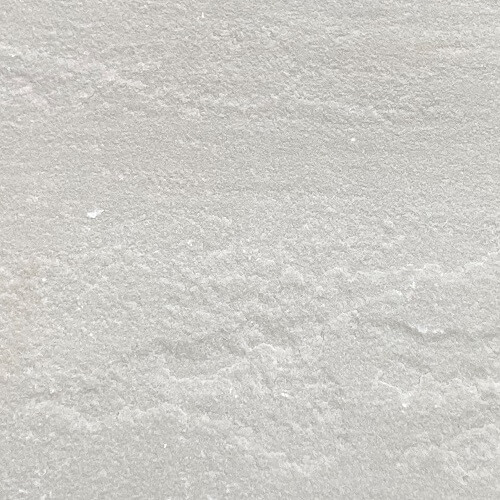

India Slate and quartzite series

These are color variations of natural stone sheets made from Indian slate or quartzite peeled into thin sheets.

There are other types of slate and quartzite available, and we will post additional information as soon as slab materials are collected.

India Sandstone Series

This is a color variation of natural stone sheet made from thinly peeled Indian sandstone in sheet form.

There are other types of sandstone available, and we will post additional information as soon as the slab material is gathered.

China Sandstone Series

This is a color variation of natural stone sheet made from thinly peeled Chinese sandstone in sheet form.

Chinese sandstone has a coloring that the Japanese prefer, making it ideal for Japanese-style rooms.

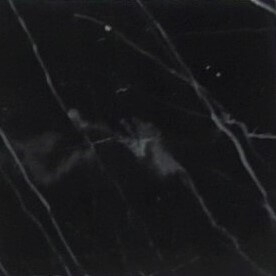

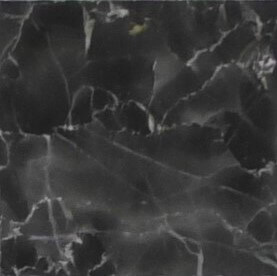

India Marble Series

This is a color variation of natural stone sheets made from thinly peeled Indian marble in sheet form.

There are other types of marble available, and we will post additional information as soon as the slab material is collected.

Marble panel (thin, light, durable, glossy)

glossy marble natural stone sheet

Our newly developed marble panel was born from a customer’s request for a glossy marble natural stone sheet.

A typical marble natural stone sheet is made by peeling off a thin layer of marble, so the surface is not polished and therefore lacks luster. Therefore, we created this marble panel by thinly slicing marble with a polished surface.

When marble is sliced into 2mm thin pieces, it breaks extremely easily, making it difficult to use as wall material. However, by backing it with FRC (fiber-reinforced ceramic) and calcium silicate board developed by our company to give it strength, we have developed a thin, light, and glossy marble panel.

The size of the marble panel in the image is 300 square meters, and it weighs 876g. The marble is sliced into 2mm pieces and bonded to a 4mm calcium silicate board with a 0.6mm FRC board to give it strength. Of course, it is completely non-combustible.

Generally, the thickness of marble that is pasted on walls is 10 mm to 15 mm, so by using our marble panels (6.6 mm thick), you can significantly reduce weight and cost.

Characteristics of marble panels developed by EDM

- Shiny (luxury)

- Thin (low cost)

- Light (easy to install due to its light weight)

- Durable (strength guaranteed by FRC and calcium silicate board lining)

- Completely non-combustible

Marble panel color variations

*Products can also be provided with marble color variations other than those listed. There are other types of marble, so we will post them from time to time.

Difference between commercially available natural stone sheets and natural stone sheets made by Each DreaM

| Commercially available natural stone sheets | Natural stone sheet made by EDM | |

| natural stone | 〇 | 〇 |

| non-combustibility | × | 〇 |

| flexibility | 〇 | 〇 |

| thickness | Approx. 1.5 mm to 3 mm | Approx. 0.8 mm to 1.5 mm |

| Ease of processing | Can be cut with scissors | Can be cut with scissors |

| reinforcing material | Resin, glass fiber, cotton mesh, double-sided tape | Fiber Reinforced Ceramic Solution, Basalt fiber |

| Noncombustible material certification | × Acquisition is not possible | 〇 Passed ISO-5660 |

| Formaldehyde emission test | — | 0.0 mg/L (Fiber-reinforced ceramic plates used as reinforcement) |

- The major difference between commercially available natural stone sheets and those made by EDM is their noncombustibility.

- Natural stone sheets sold around the world reinforce the strength of natural stone with resin and fiberglass. Therefore, in the event of a fire, even if the natural stone does not burn, the resin of the reinforcement material will burn, as will the adhesive and double-sided tape that adheres it to the wall. Toxic gases are also produced in case of fire.

Natural stone sheets made of EDM are backed with Basalt Fiber Reinforced Ceramic (FRC), our special technology, and the entire structure is made of noncombustible material, so it will not burn and will not emit toxic gases.

The product has passed the ISO-5660 nonflammability test.

Construction method (How to paste)

The installation method is similar to commercially available natural stone sheets, and can be easily pasted using architectural adhesive or double-sided tape. In the event of a fire, it will not ignite immediately due to the stone surface and FRC layer. However, over time, the double-sided tape and adhesive on the inside will heat up and generate gas and smoke, but this will buy you a considerable amount of time to evacuate. When bonding with construction adhesive, we recommend a natural stone board made by pressing a natural stone sheet onto a Keikal board with our noncombustible material. With natural stone boards, heat is suppressed by the natural stone sheet and calcium silicate board, so the heat does not reach the adhesive on the back, so the adhesive does not burn.

- Check the installation position by measuring the horizontal and dimensions.

- Level the surface using a laser marker, measure the dimensions with a scale, and confirm the position where the natural stone sheet will be attached. The key to making it look beautiful is to paste it from the center and adjust it at the left and right edges.

- Apply double-sided tape to the back of the natural stone sheet.

- First, attach double-sided tape to the back of the natural stone sheet. The reason for applying double-sided tape is that adhesive alone will move around until it dries and hardens, so it is necessary to firmly fix the natural stone sheet.

- Apply board adhesive to the inside of the double-sided tape.

- Next, apply board adhesive to the inside of the double-sided tape. By doing so, the double-sided tape will prevent the adhesive from seeping out.

- Paste the natural stone sheet.

- Paste the natural stone sheet.

- Rollers are used to spread the adhesive on the inside.

- Rollers are used to spread the adhesive on the inside.

Construction results

Frequently Asked Questions (Q&A)

Has it passed the noncombustible materials certification by the Minister of Land, Infrastructure, Transport and Tourism?

Yes. Both natural stone sheet and natural stone board have passed the Ministry of Land, Infrastructure, Transport and Tourism’s noncombustible materials certification in April 2023.

Natural stone sheet is a thinly peeled sheet of natural stone, while natural stone board is a board made of natural stone sheet crimped to a calcium carbonate board.

It has passed the gas toxicity test certified as noncombustible by the Ministry of Land, Infrastructure, Transport and Tourism, and does not emit any toxic gases.

- Are there any natural stone sheets other than the color variations shown in the catalog?

Since natural stone sheets are made of real natural stone, no two are exactly alike, and there is variation in color.

There are many natural stone sheets available in colors other than those shown in the catalog, so please contact us for more information.

- Is the thickness of the natural stone sheet constant?

Since natural stones are thinly peeled by hand along the cleaved surface to form sheets, the thickness is not consistent.

The uneven appearance of the peeled natural stone is very unique and is the beauty and charm of natural stone sheets.

- Is the installation method (how to apply) the same as for general natural stone sheets?

Like ordinary natural stone sheets, it can be installed by bonding it to the wall with adhesives or double-sided tape. However, when bonded with adhesives or double-sided tape, it will burn in the event of a fire, but will not ignite immediately due to the stone surface and FRC layer. Over time, the double-sided tape or adhesive on the inner surface will generate gas or smoke due to heating, but this will give you a considerable amount of time to evacuate the area.

In addition, with our natural stone board, even in the event of fire, the natural stone sheet and the calcium silicate board will prevent heat from reaching the back of the calcium silicate board, which is the reinforcing material.

- What is the heat resistance temperature of natural stone sheets?

The heat resistance temperature of slate and sandstone used for natural stone sheets is 1000°C. The heat resistance temperature of marble and limestone is 600°C.

The reinforcement part of the natural stone sheet is made of Fiber Reinforced Ceramics (FRC) developed by our company, which does not burn even at a temperature of 1200℃.

Is there any surface treatment?

We have done nothing. As an antifouling measure, we recommend applying a nonflammable glass paint to the surface. The stone has a water absorption rate that allows a small amount of water to soak into the stone, so by applying a nonflammable glass paint that does not change color after application, the water is repelled and the stone is resistant to staining. This glass paint is an antifouling measure and does not harden the surface.